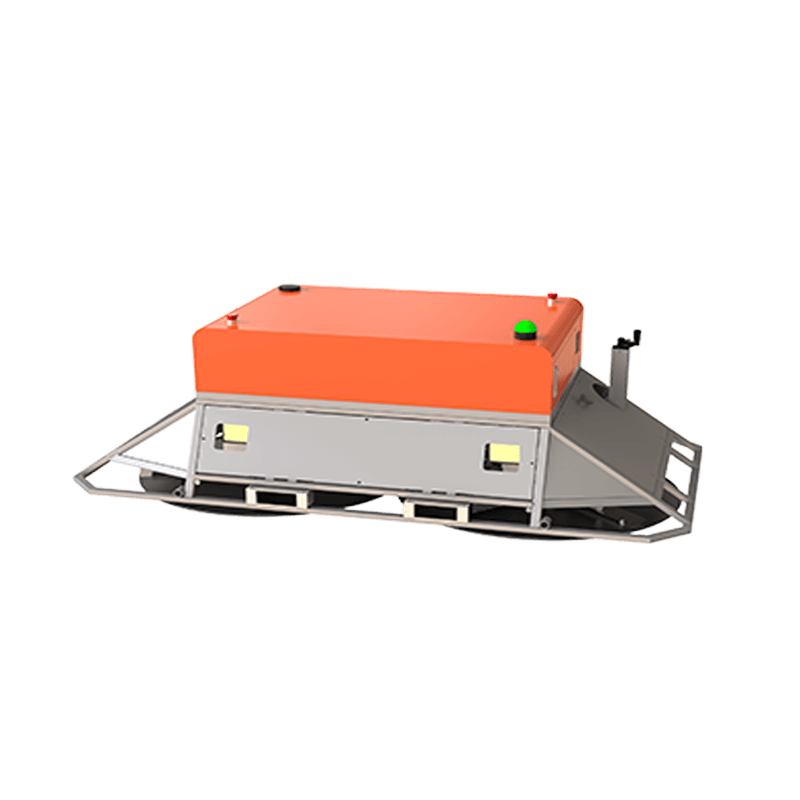

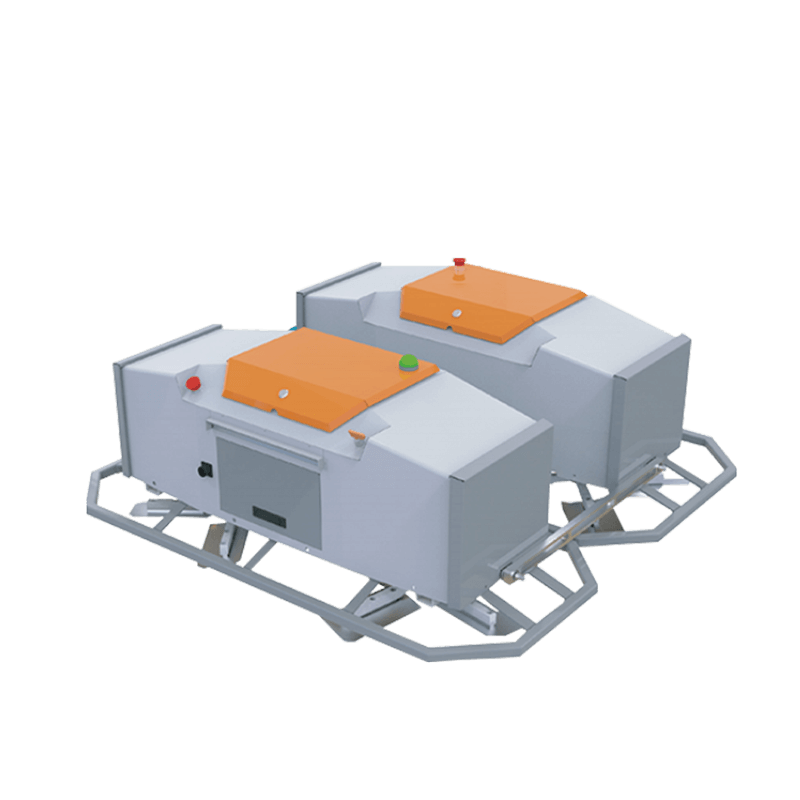

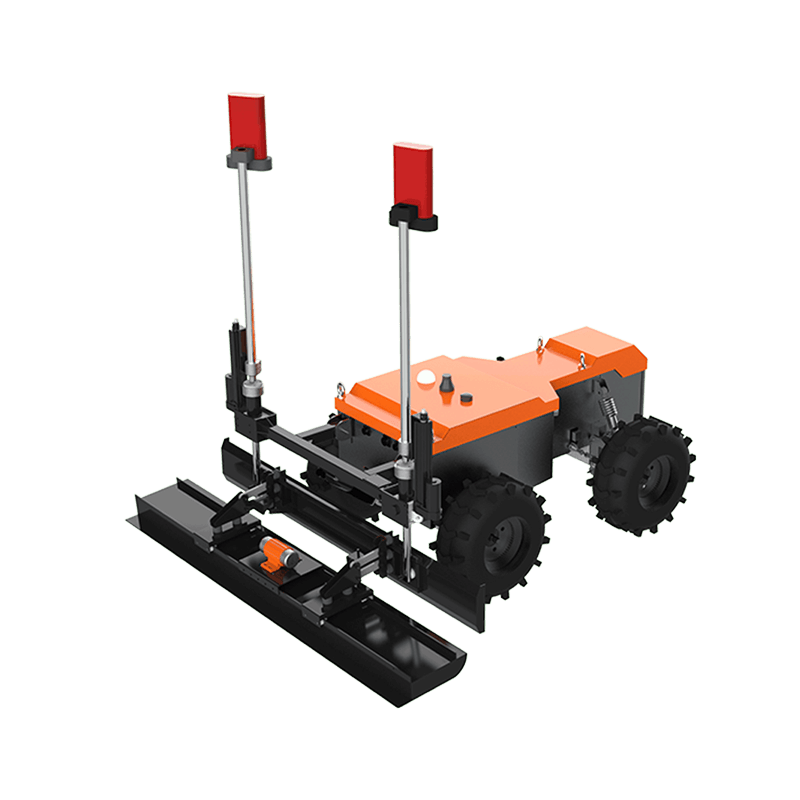

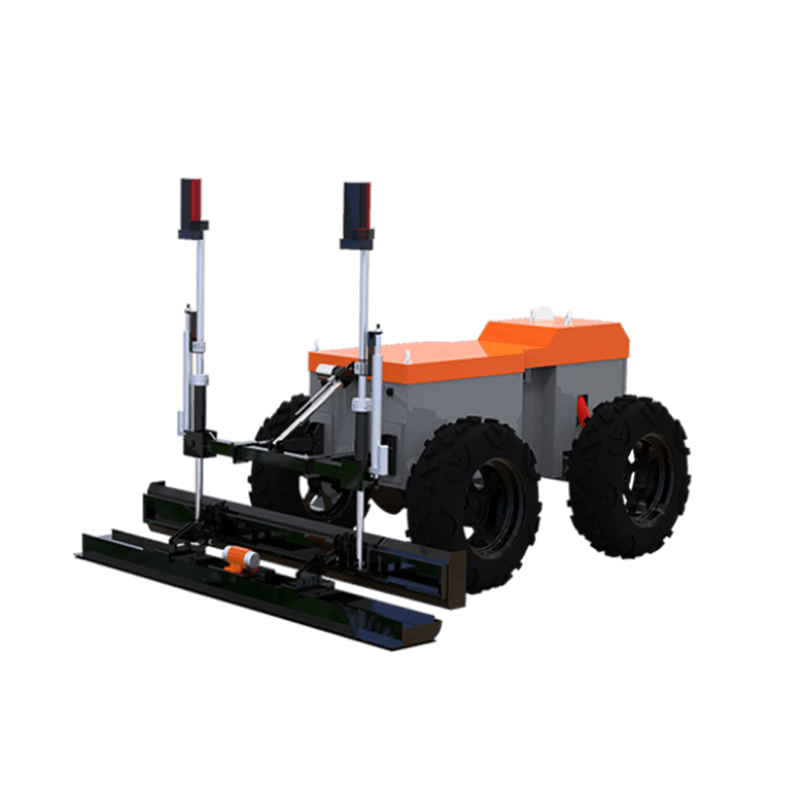

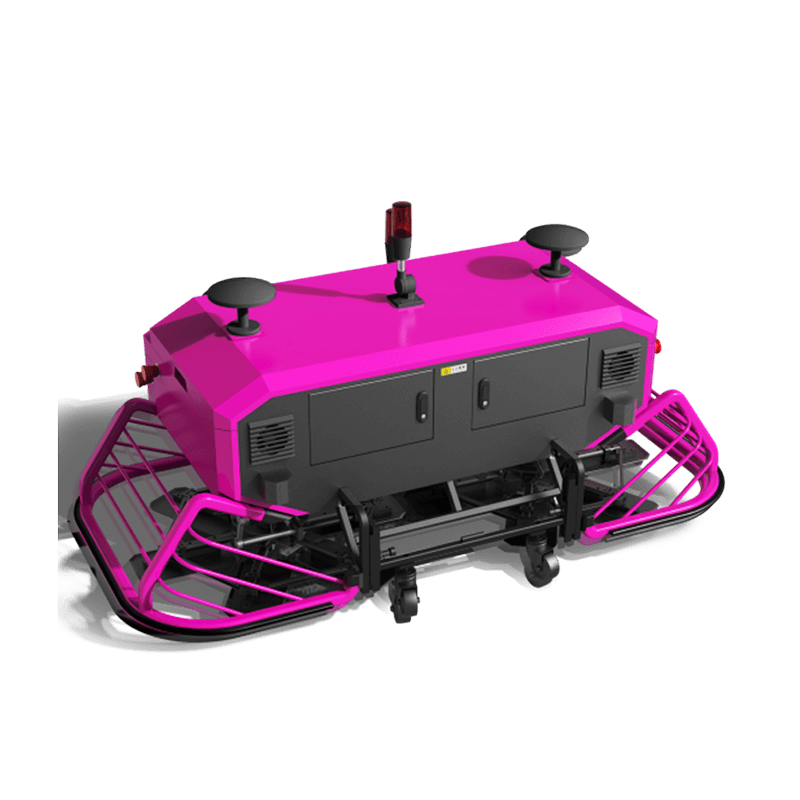

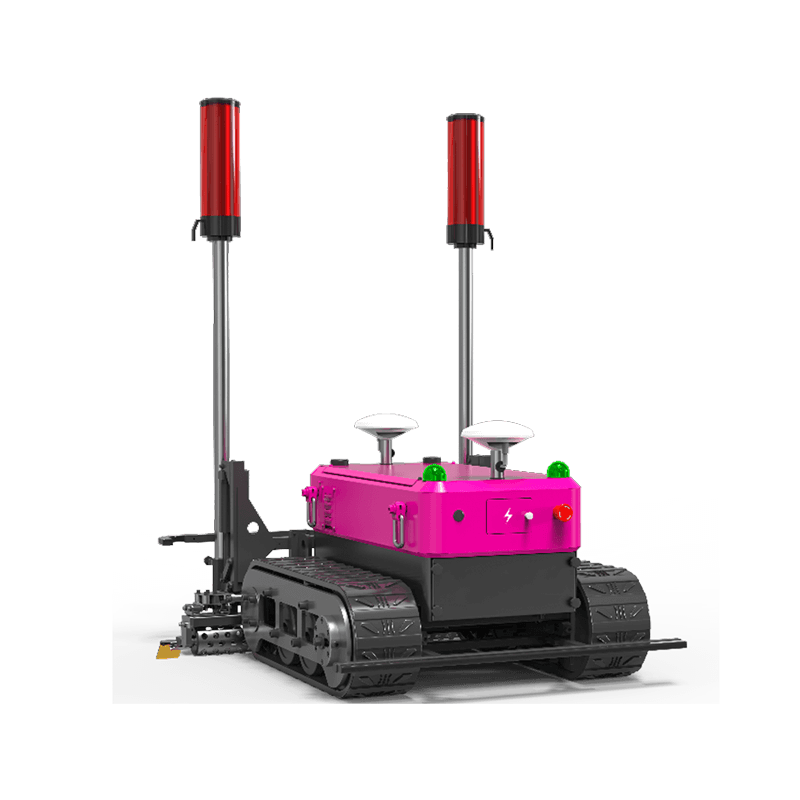

Intelligent Follow-up Concrete Placing Equiment construction AI Robot

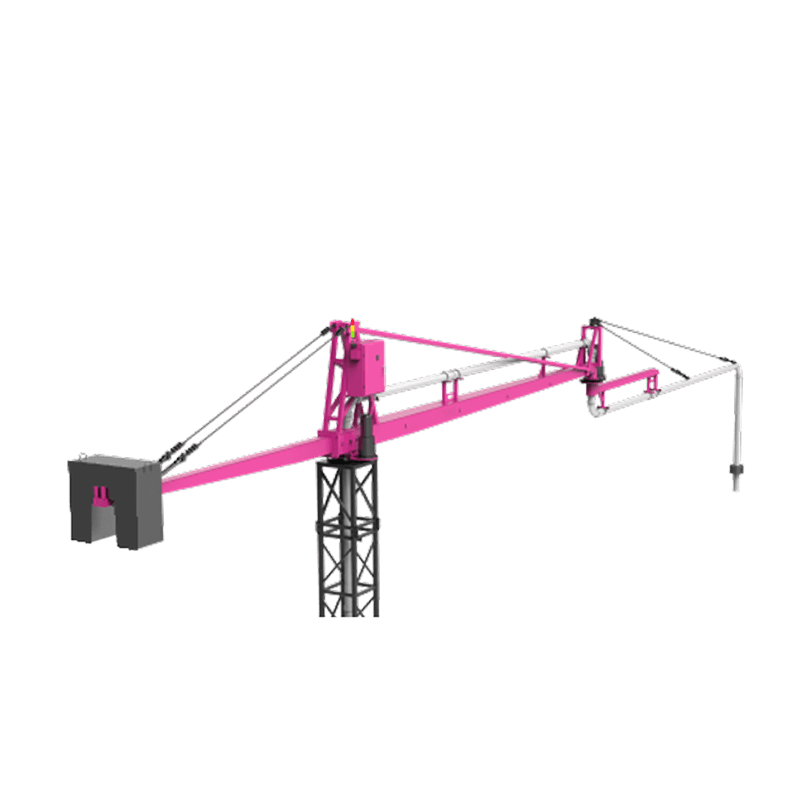

The robot is divided into four models based on different fabric radius requirements: 12, 15, 18, and 20 meters, suitable for concrete fabric operations on different floors and basements.

Follow up fabric function: By controlling the movement of the large and small arms through algorithms, fabric work can be completed with only 30% manpower.

Automatic fabric function: With the advantage of high uniformity of automatic fabric, it reduces the leveling workload by 13% and helps achieve high-precision flooring for standard layers.

Multi mode switching function: It can switch between four modes: automatic/follow-up/jog/manual, ensuring that the fabric work is not delayed in any situation.

Product Description

| Product Parameters | |||||||

| Model | Overall Weight (T) (Excluding Counterweight) | Minimum Weight for Transfer Between Floors (T) | Maximum Material Distribution Radius (m) | Installation Dimensions (m) | Operating Voltage (V) | Product Functions | Maximum Withstand Wind Force |

| 20m | 3.3 | 2.5 | 20 |

Reserved opening: 1.2×1.2 – 1.5×1.5 |

Three – phase five – wire AC380V (±40V) |

Automatic mode (Automatic material distribution according to preset path) |

13.8m/s (Grade 6 wind) |

| 18m | 3.1 | 2.2 | 18 |

Elevator shaft installation: 2.1×2.1 – 2.3×2.3 |

Follow – up mode (Single – person handle operation) |

||

| 15m | 1.7 | 1.7 (2.2) | 15 |

Outrigger span: 4.2×4.2 |

Point – action mode (Remote control of large and small arms) |

||

| 12m | 1.6 | 1.6 (2.2) | 12 |

Outrigger span: 3.6×3.6 |

Manual mode (Traditional manual pulling) |

||